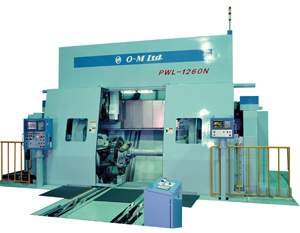

PWL-1150N/PWL-1260N(CNC Wheel Lathe)

This machine automatically probes and reprofiles wheel tread on the left and right on axles simultaneously with the axle box removed.

Main Features

- High rigidity one piece portal type columns, and high precision large diameter spindles make deep cuts possible.

Max. 20mm (diameter value)

- Chip disposal is smooth

Smooth chip disposal by utilizing a fully closed type cover

- Fully automatic probing is possible

Diameter of wheel tread, flange thickness, flange height, wheel width, distance between inner surfaces, vibration of inner surfaces, vibration of tread

- Ten cutting tools are installed

Setting of spare tools is possible

Description

| MAX. wheel daimeter | 1150mm |

| MIN. wheel diameter | 600mm |

| MAX. Axle length(Gauge 1067mm / 1435mm) | 2250 / 2620 |

| MIN. Axle length(Gauge 1067mm / 1435mm) | 1360 / 1730 |

| Wheel width | 122 ~ 140 |

| No.of Tool head | 2 |

| No.of tools | 10 |

| Maximum cutting depth | 10 |

Head stock

| Center height (From rail top) | 750mm | ||

| Face plate diameter | 1360mm | ||

| Clamp diameter | Jaw center diameter | Max. | 1100mm |

| Min. | 600mm | ||

| Distance between face plates | At gauge 1067 | Processing position | 2250mm |

| Stand-by position | 3300mm | ||

| At gauge 1435 | Processing position | 2620mm | |

| Stand-by position | 3670mm | ||

| Face plate rotation speed | 2~48min-1 (Variable speed) |

||

| Max. cutting force | 44100N | ||

| Max. turning force | 43600N・m | ||

| Max. allowable wheel mass | 2500kg | ||

Tool post

| X-axis (vertical) travel (one tool post) | 535mm | |

| Z-axis (horizontal) travel (one tool post) | 595mm | |

| Cutting feed rate | X axis | 0.1~3.0 mm/rev |

| Z axis | 0.1~3.0 mm/rev | |

| Rapid feed rate | X axis | 5000 mm/min |

| Z axis | 7000 mm/min | |

| Number of turret indexing positions | 10 positions | |

Machine mass

| Machine body | 58000kg |

| Hydraulic power unit | 800kg |

| Control panel | 900kg |